360 Degree Excavator 14 Tonne Upwards

Main Function

Excavating earth, sand, waste, rock in construction sites, quarries, road building project etc, digging trenches, landscaping, rock breaking, dredging and a lot more!

General Description

If not referred to as a mini digger the 360 degree excavators usually describes machines weighing over 8.5 tonnes. The 360 degree excavator is an amazing tool valued by all sectors of heavy industry from construction to recycling, quarrying to demolition. It’s a powerful highly manoeuvrable machine, most commonly they sit on steel caterpillar tracks which can give low ground pressure and the ability to climb up the steepest of slopes.

Design

The main principle of a having a cab and arm rotating round the chassis is a very old one. Some of the first bucket loaders consisted of this same basic design dating back over 100 years, were ropes were used instead of hydraulics. So the design is definitely time proven. Today the rapid manoeuvrability of an excavator 360 degrees around its chassis makes them ideal for digging and loading lorries or dumpers very fast. The advanced hydraulics systems make them very precise at excavating trenches. The variety of these machines is huge, made to for fill many different purposes. They can be on rubber tracks, steel tracks, rubber tyres, steel railway tyres or even boats. The chassis can be attached with blades, hydraulic legs, or snowploughs. Some machines have raising cabs to help see into enhance visibility. The varieties in the main boom and dipping arm keep on growing, with long reach and short booms, extra booms, extending booms, swinging booms, powerslide booms, 360 degree excavators today have more uses than a Swiss army knife but the most commonly used and seen is the design pictured below which has a standard chassis with steel caterpillar tracks, a main boom and dipping arm attached to a cab which can rotate 360 degrees about the chassis. As shown below:

Model Variations

Zero Swing excavators are now a common feature of smaller excavtors, but they are now being introduced into the larger machines. The picture above of the Volvo EC360C shows the classic shape of an 360 excavator, where the counterweight hangs over the tracks for added stability. However when working with smaller machines in tighter spaces the counterweight is often found to be in the way. So a quite recently excavator manufacturer Yanmar started making zero swing excavators where the counterweight did not overhang the tracks yet the machine remained stable. Quickly most manufacturers followed suit and now many of the smaller excavators are available with a zero swing model. The picture below shows an example of a Volvo ECR235C

Rubber Duck is the name often given to wheeled excavators, these 360 degree excavators, have four wheel drive a pneumatic tyres rather than caterpillar tracks. This gives them the ability to be driven on the road legally and without damaging the tarmac. Below shows a picture of the Terex T110, with is four wheel drive all wheel steering chassis.

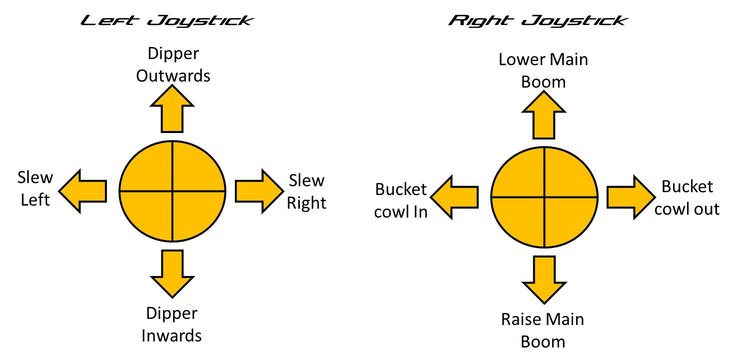

360 Degree Excavator Controls

Most 360 degree excavators follow the European standard controls to increase safety for operators, the standard joystick controls are shown below:

Buckets and attachments

There is a huge range of buckets and attachments available for these machines, below are links to pages on some of the attachments available.

Quick release mechanism

Standard buckets

Ditching bucket

Riddle and screening buckets

Crushing buckets

Hydraulic hammer

Hydraulic shear

Vibrating plate attachment

Grapple

Chainsaw attachments

Forestry attachments

360 Degree Excavator Manufacturers

Common manufacturers Include:

Volvo

Terex

Caterpillar

Samsung

Kobelco

Hitachi

Case

JCB